ZKT-750B

Window Patching Machine

product details

Summarize

ZKT-750B Window Patching Machine can apply window film to all kinds of paper boxes. Based on the original window patching machines, it is a fruit by referring to customers’ feedback and our continual improvement and philosophy of humanized design. It is easy to operate and excellent in efficiency, accuracy and stability. ZKT-750B Window Patching Machine employs a multi-servo control system. Our proprietary technology is embodied in both basic companents and automation parts of this product. Therefore, it is in the position to meet customers’ requirements at a higher level.

Structure Characteristics

1.The paper feeder is driven by a servo of a famous brand. Paper is delivered on the bottom via an intermittent belt, so paper can be fed continuously without shutdown. The paper feeder is controlled by PLC. lt has a human-machine interface, on which you can enter the length of paper to be fed, so that paper can be supplied quickly and accurately. Also, the paper feeder applies to card paper and corrugated paper.

2.

(1)it is easy to adjust the basic part of the film feeder left and right in parallel.

(2) The film feeder is controlled by a servo control system of a famous brand. It is only required to enter the length to be cut on the touch screen, which improves accuracy and makes adjustment easy.

(3) The film feeder can cut corners and creasing lines automatically. It applies to products subject to single (double) line creasing and corner cutting. Also it can be adjusted at will.

3.

(1) The sizing section consists of chromed sizing roller,glue separating guide, side limiter and sizing template roller. It is easy to pull out, set and clean the sizing section.

(2) The glue separating guide can be adjusted to control I the range and amount of glue. In the event of shutdown,the cylinder can raise the sizing roller and it is driven by the other independent motor to avoid glue solidification.

(3) Without shutdown, the gluing roller can be adjusted freely on an axial or radial basis.

4.The paper collector is designed as a belt and final product can be stacked in order.

2.

(1)it is easy to adjust the basic part of the film feeder left and right in parallel.

(2) The film feeder is controlled by a servo control system of a famous brand. It is only required to enter the length to be cut on the touch screen, which improves accuracy and makes adjustment easy.

(3) The film feeder can cut corners and creasing lines automatically. It applies to products subject to single (double) line creasing and corner cutting. Also it can be adjusted at will.

3.

(1) The sizing section consists of chromed sizing roller,glue separating guide, side limiter and sizing template roller. It is easy to pull out, set and clean the sizing section.

(2) The glue separating guide can be adjusted to control I the range and amount of glue. In the event of shutdown,the cylinder can raise the sizing roller and it is driven by the other independent motor to avoid glue solidification.

(3) Without shutdown, the gluing roller can be adjusted freely on an axial or radial basis.

4.The paper collector is designed as a belt and final product can be stacked in order.

Application scope

Servo System: Yaskawa

Relay: Omron

Plc: Panasonic

Frequency converter: Toshiba

Power switch : Schneider

Switch button: Schneider

Circuit Breaker: Schneider

Contactor: Schneider

Encoder: Omron

Photo Electric Sensor: Panasonic

Solenoid valve: SMC

Bearing:NSK

Relay: Omron

Plc: Panasonic

Frequency converter: Toshiba

Power switch : Schneider

Switch button: Schneider

Circuit Breaker: Schneider

Contactor: Schneider

Encoder: Omron

Photo Electric Sensor: Panasonic

Solenoid valve: SMC

Bearing:NSK

Technical parameter

| Model | ZKT-750B贴窗机 |

| Speed | 6000-10000pcs/h(Flat film patching) |

| 4000-7000pcs/h(V-cut and creasing) | |

| Paper Length | 140-600mm |

| Paper Width | 120-750mm |

| Film Length | 60-350mm |

| Film Width | 30-400mm |

| Thickness of Film | 0.03-0.25mm |

| Main Power | 2.2kw |

| Power of Pump | 1.5kw |

| External Dimension | 5000×1550×1770mm |

| Weight | 2800kg |

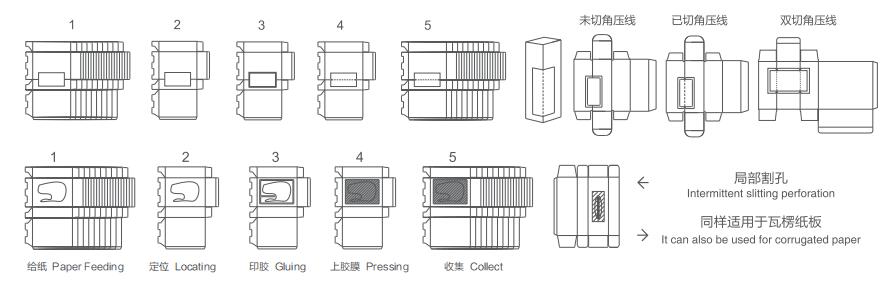

Production Process

Sample