ZKT-700B、1080B

Window Patching Machine

product details

Summarize

700 Series window Patching Machine is used to film the windows of various paper boxes.It is developed on the original window patching machine in light of customers’ requirements requirements.Our research and development team,through the continuous improved & perfect human design,let the machines be easier to operate and better in efficiency,accuracy and stability,Both basic components and major automated accessories employ the proprietary technology of this company.Therefore,700 Series Window Patching Machine can meet customers’ requirements at a higher level

Structure Characteristics

1.The paper feeder is controlled by PLC with a human-computer interface. The length of paper to be fed can be entered on the touch screen, so that paper can be input quickly and accurately. Also, it applies to card paper and corrugated paper.

2.The film feeder is controlled by a servo control system of a famous internation-al brand. The length of film to be cut can be entered on the touch screen. Not only can film be cut accurately, but also adjustment can be made more quickly and directly.

3.The gluing section adopted pneumatic principle,and can glue on particular part according to the window position, so no need to glue the whole roller, making it easier to clean the roller as well as saving the glue.

4.Film cutter is equipped with a axis of rotation, so to suit variable window position. It can saving the machine-adjustment time and improve productivity.

5.ZKT-700B is widely used in 90 degrees angle window samples, and can do the angle cutting and creasing.

6. The paper and film feeding sections are equipped with a chain guide imported from Germany and a linear guide imported from Taiwan, and other accessories, which helps improve film patching accuracy and reduce noise.

7.Compared to the previous machine, each section of this product has improved,thus saving the adjustment time, making it more efficient and friendly in use.

2.The film feeder is controlled by a servo control system of a famous internation-al brand. The length of film to be cut can be entered on the touch screen. Not only can film be cut accurately, but also adjustment can be made more quickly and directly.

3.The gluing section adopted pneumatic principle,and can glue on particular part according to the window position, so no need to glue the whole roller, making it easier to clean the roller as well as saving the glue.

4.Film cutter is equipped with a axis of rotation, so to suit variable window position. It can saving the machine-adjustment time and improve productivity.

5.ZKT-700B is widely used in 90 degrees angle window samples, and can do the angle cutting and creasing.

6. The paper and film feeding sections are equipped with a chain guide imported from Germany and a linear guide imported from Taiwan, and other accessories, which helps improve film patching accuracy and reduce noise.

7.Compared to the previous machine, each section of this product has improved,thus saving the adjustment time, making it more efficient and friendly in use.

Application scope

Servo System Yaskawa / Dorna

Relay: Omron

Plc: Panasonic

Frequency converter:Toshiba

Power switch : Schneider

Switch button: Schneider

Motor:Anhui Wannan

Relay: Omron

Plc: Panasonic

Frequency converter:Toshiba

Power switch : Schneider

Switch button: Schneider

Motor:Anhui Wannan

Technical parameter

| Model | ZKT-700B | ZKT-1080B |

| Speed | 6000-10000pcs/h(Flat film patching) | 6000-10000pcs/h(Flat film patching) |

| 4000-7000pcs/h(V-cut and creasing) | 4000-7000pcs/h(V-cut and creasing) | |

| Paper Length | 140 - 600mm | 200-700mm |

| Paper Width | 140 - 690mm | 200-1080mm |

| Film Length | 0.03-0.25mm | 0.03-0.25mm |

| Film Width | 60- 400mm | 70- 400mm |

| Thickness of Film | 30 - 400mm | 30 - 500mm |

| Main Power | 2.2kw | 2.2kw |

| Power of Pump | 1.5kw | 1.5kw |

| External Dimension | 4200×1400×1500mm | 5500x1900x1600mm |

| Weight | 2800 kg | 3500kg |

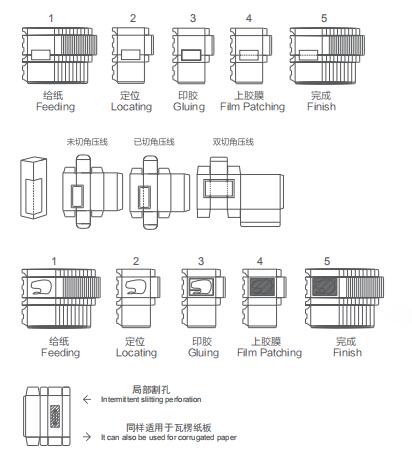

Production Process

Sample