ZKT-700/1080

High Speed Window Patching Machine

product details

Summarize

700 Series window Patching Machine is used to film the windows of various paper boxes.It is developed on the original window patching machine in light of customers’ requirements requirements.Our research and development team,through the continuous improved & perfect human design,let the machines be easier to operate and better in efficiency,accuracy and stability,Both basic components and major automated accessories employ the proprietary technology of this company.Therefore,700 Series Window Patching Machine can meet customers’ requirements at a higher level

Structure Characteristics

1. The paper feeder adopts photoelectric control, so it is not needed to adjust paper length by hand, thus making paper feeding easy, quick and accurate. It applies to card paper and corrugated paper.

2. The film feeder has an imported servo control system. It is OK to input cutting length on the touch screen, which helps improve precision and facilitate adjustment.

3. The gluing section consists of chrome-plated sizing roller, glue separating guide, side limit and gluing stencil roller. It can be pulled out easily, which simplifies both setting and cleaning. The adjustable glue separating guide can control gluing range and glue volume. After shutdown, the cylinder raises the gluing roller and drives it with a separate motor to prevent glue from solidifying.The printing roller can be adjusted freely in the axial and radial directions without being stopped.

4. A device on the film cutter can rotate axially freely in order to fit different window positions, which helps save the adjustment time and improve efficiency significantly.

5. Compared to the previous machine, each section of this product has improved, thus saving the adjustment time, making it more efficient and friendly in use.

6. The paper and film feeding sections are equipped with a chain guide imported from Germany and a linear guide imported from Taiwan, and other accessories,which helps improve film patching accuracy and reduce noise.

7. The touch screen is equipped with a speed shifting unit. So it can double speed for small-sized products.

2. The film feeder has an imported servo control system. It is OK to input cutting length on the touch screen, which helps improve precision and facilitate adjustment.

3. The gluing section consists of chrome-plated sizing roller, glue separating guide, side limit and gluing stencil roller. It can be pulled out easily, which simplifies both setting and cleaning. The adjustable glue separating guide can control gluing range and glue volume. After shutdown, the cylinder raises the gluing roller and drives it with a separate motor to prevent glue from solidifying.The printing roller can be adjusted freely in the axial and radial directions without being stopped.

4. A device on the film cutter can rotate axially freely in order to fit different window positions, which helps save the adjustment time and improve efficiency significantly.

5. Compared to the previous machine, each section of this product has improved, thus saving the adjustment time, making it more efficient and friendly in use.

6. The paper and film feeding sections are equipped with a chain guide imported from Germany and a linear guide imported from Taiwan, and other accessories,which helps improve film patching accuracy and reduce noise.

7. The touch screen is equipped with a speed shifting unit. So it can double speed for small-sized products.

Application scope

Servo System Yaskawa / Dorna

Relay: Omron

Plc: Panasonic

Frequency converter: Toshiba

Power switch : Schneider

Switch button: Schneider

Motor:Anhui Wannan

Relay: Omron

Plc: Panasonic

Frequency converter: Toshiba

Power switch : Schneider

Switch button: Schneider

Motor:Anhui Wannan

Technical parameter

| Model | ZKT-700 | ZKT-1080 |

|

Speed (speed can changed according to the paper size) |

7000-31000pcs/h | 6000-18000pcs/h |

| Paper Length | 160-680mm | 160-700mm |

| Paper Width | 120-700mm | 120-1080mm |

| Film Length | 60-330mm | 70-330mm |

| Film Width | 30-400mm | 30-500mm |

| Thickness of Film | 0.03-0.25mm | 0.03-0.25mm |

| Main Power | 2.2kw | 2.2kw |

| Power of Pump | 1.5kw | 1.5kw |

| External Dimension | 6200×1580×1700mm | 4200×1400×1500mm |

| Weight | 2300kg | 2600kg |

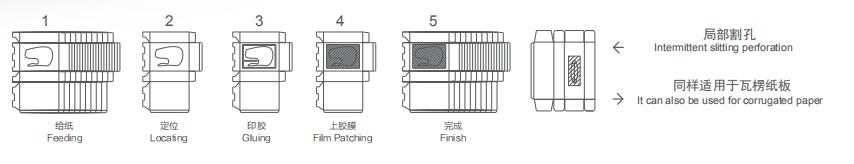

Production Process

Sample